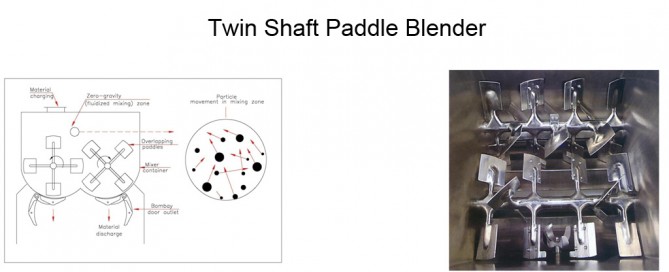

Twin Shaft Paddle Blender

- Paddles mounted on twin shafts in a ‘w’ shaped trough

- Normal filling level of material in the mixer is slightly above the shafts

- Overlapping motion and paddle design facilitates rapid fluidization and ensures excellent movement of particles

- Surplus space in the mixer trough to provide air around the particles so that they can move freely

- Twin shaft, counter-rotating paddles lift the particles in the centre of the mixer trough, in the fluidized zone, where mixing takes place in a weightless state

- Normal working volume is about 25 percent of the total volume of the trough

- Range of operation of the mixer is 40 to 140 percent of the rated capacity

- Peripheral speed ~100 metres per minute

- Mixing time can be as low as 1 minute. Mixing homogeneity of 98 – 99 percent.

- Choice of discharge valves including half bomb bay doors, spherical disc valves are available.

- High speed choppers can be provided

- Rotating twin shaft paddle mixers are the most recent development.

Related Links

- Double Cone Blender – Consists of two conical sections separated by a central cylindrical section…Read more..

- V Blender – Two hollow cylindrical shells joined at an angle of 75 degrees to 90 degrees..Read more

- Ribbon Blender – U-shaped horizontal trough containing a rotating double helical ribbon or paddle agitator..Read more

- Paddle Blender – A design alternative to the ribbon agitator is the paddle agitator, which can handle fragile material..Read more

- Vertical Cone Screw Blender – Consists of a conical shape vessel with a screw agitator that rotates about its own axis while orbiting around the vessel’s periphery..Read more

- Plow Mixer – Operate on the principle of a mechanically generated fluid bed with three dimensional movement of the product..Read more

- Mechanical Silo Blender – Provided with a screw housed in a cylindrical shell, isolating the bulk material in the silo from the material inside the shell..Read more

Social Network Links