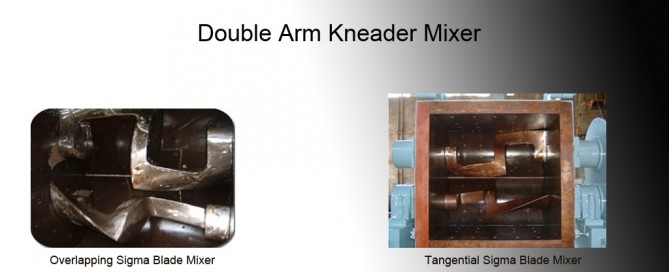

Double Arm Kneader Mixer

- Two mixing blades placed in a ‘w’ shaped horizontal trough

- Commonly used blade types are the sigma blade, masticator blade, spiral blade, shredder and naben blade

- Rotation of the blades is either tangential to each other or the blades may overlap within the trough.

- Blades pass the container walls and each other at close clearances generally (1-2 mm)

- The mixer bowl may be jacketed for circulation of heating or cooling media.

- Viscosity range upto 10 million cps

- Viscous mass of material is pulled, sheared, compressed, kneaded and folded by the action of the blades against the walls of the mixer trough.

- Fill Up is 40 – 65 % of bowl volume

- Mixing homogeneity upto 99 percent

- Specific power – 45 to 75 kW/ m3

- Discharge of the material from the mixer

- By tilting of the mixer container

- Bottom discharge valve

- Through an extruder, screw

Related Links

- Change Can Mixers - Like most liquid agitators are vertical configuration equipment with a vertical cylindrical vessel..Read more

- Single Planetary Mixer - Mixing element (commonly known as the beater) rotates in a planetary motion inside the mixer bowl…Read more

- Double Planetary Mixer - The double planetary mixer includes two blades that rotate on their own axes, while they orbit the mix vessel (also known as bowl) on a common axis…Read more

- Kneader Mixer - Two mixing blades placed in a ‘w’ shaped horizontal trough..Read more

- Kneader Mixer Extruder - The Kneader Extruder combines the efficiency of a double arm mixer with the convenience of extrusion screws for improved mixing and discharge of heavy viscous materials…Read more

- Roll Mill - Pair of smooth metal rolls set in the same horizontal plane, mounted on a heavy structure…Read more

- Pan Muller Mixer - Industrial equivalents of the traditional mortar and pestles…Read more

Social Network Links